- 홈

- Business

- Electrode Foundry

ELECTRODE

FOUNDRY

JR Energy Solution ensures high-quality electrode production and supply with

a group of highly experienced professionals and the ‘state-of-the-art’ facilities.

-

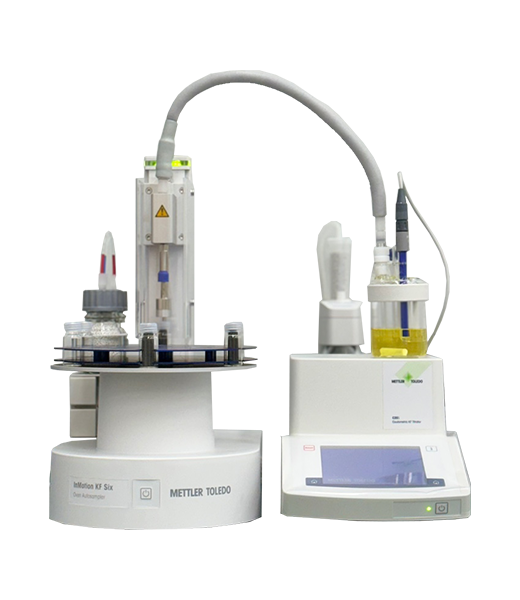

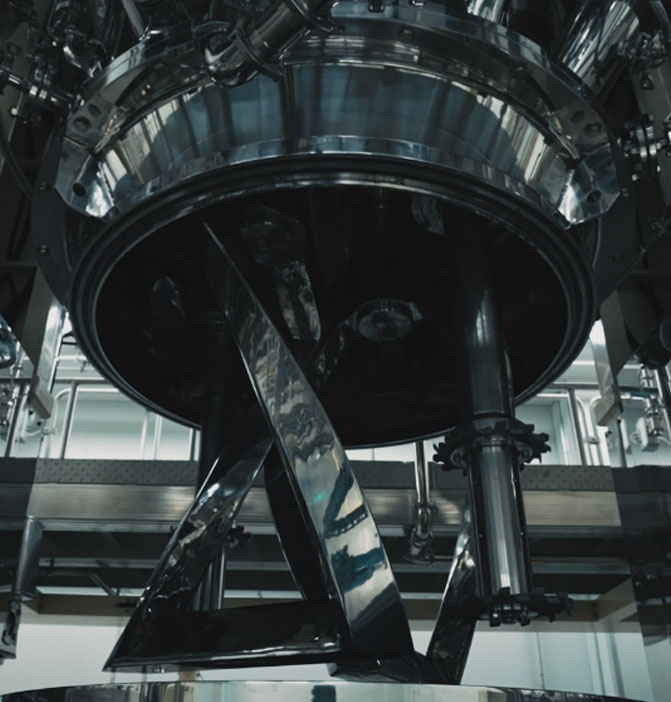

01Mixing Process

01Mixing ProcessThe mixing process involves blending anode and cathode active materials, conductive additives, and binders with solvents to create a slurry

-

02Coating Process

02Coating ProcessThe coating process involves applying the anode and cathode slurry onto foil to a specified thickness on both sides, followed by drying.

-

03Pressing Process

03Pressing ProcessThe pressing process involves applying a steady pressure to the coated foil to reduce thickness and increase density.

-

04Slitting Process

04Slitting ProcessThe slitting process involves cutting the coated foil into a specific width.

-

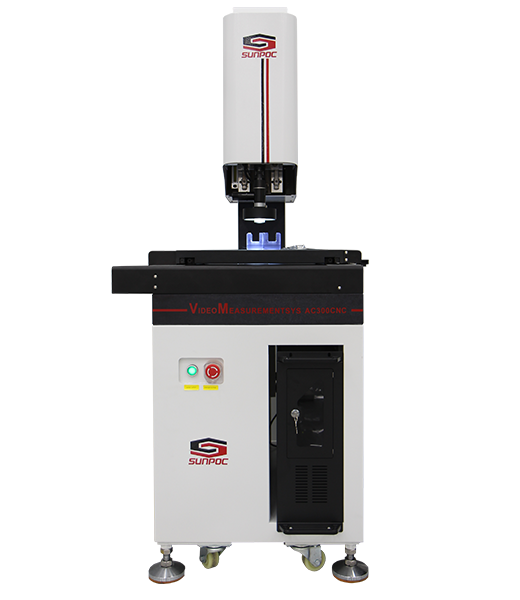

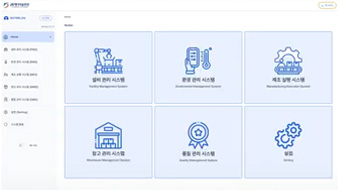

Production

Process Dashboard

Schematizing the real-time data tracking and analysis by computerizing all processes

-

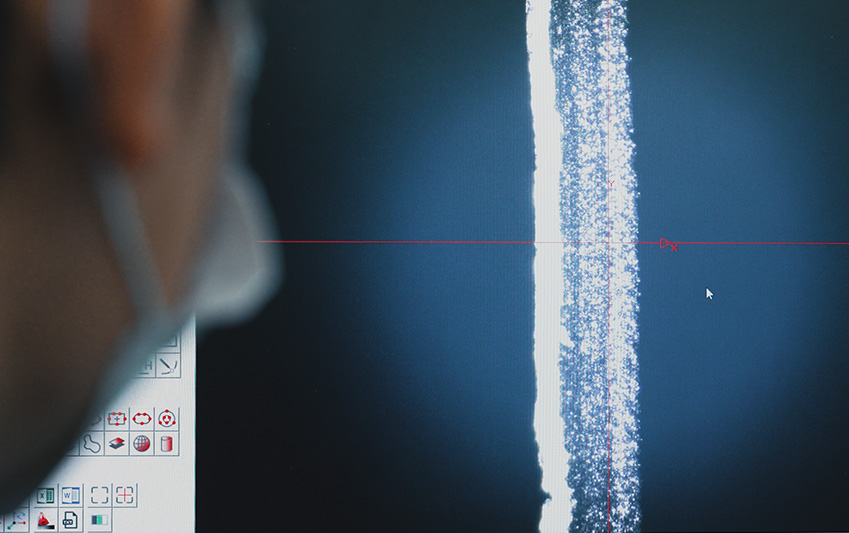

Data

Visualization

Sophisticated visualization for the intuitional interpretation and fast analysis of data

-

Monitoring

of Abnormal Detection

Providing the tool for warning the deviation of the upper and lower management limit levels set for production equipment